Horizontal Roughing

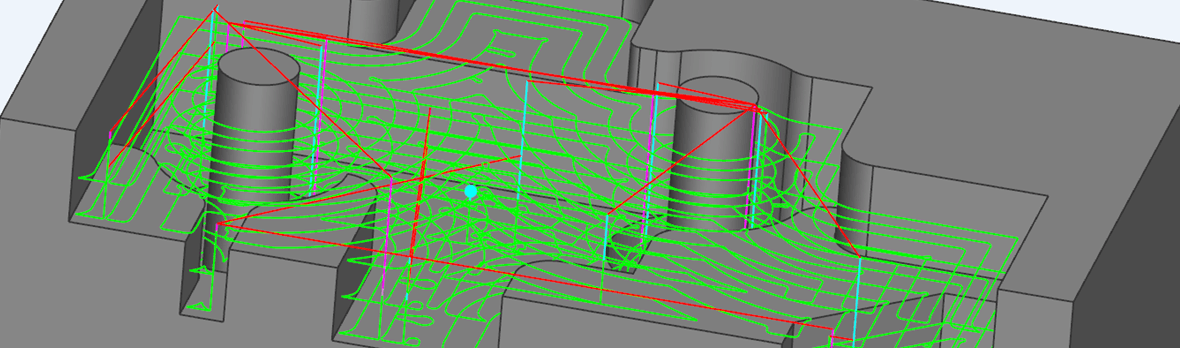

Horizontal Roughing - Offset

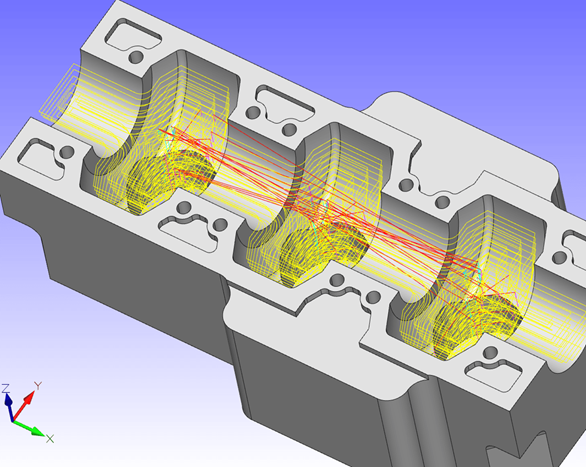

Horizontal Roughing - Offset Horizontal Roughing - Offset/Modell

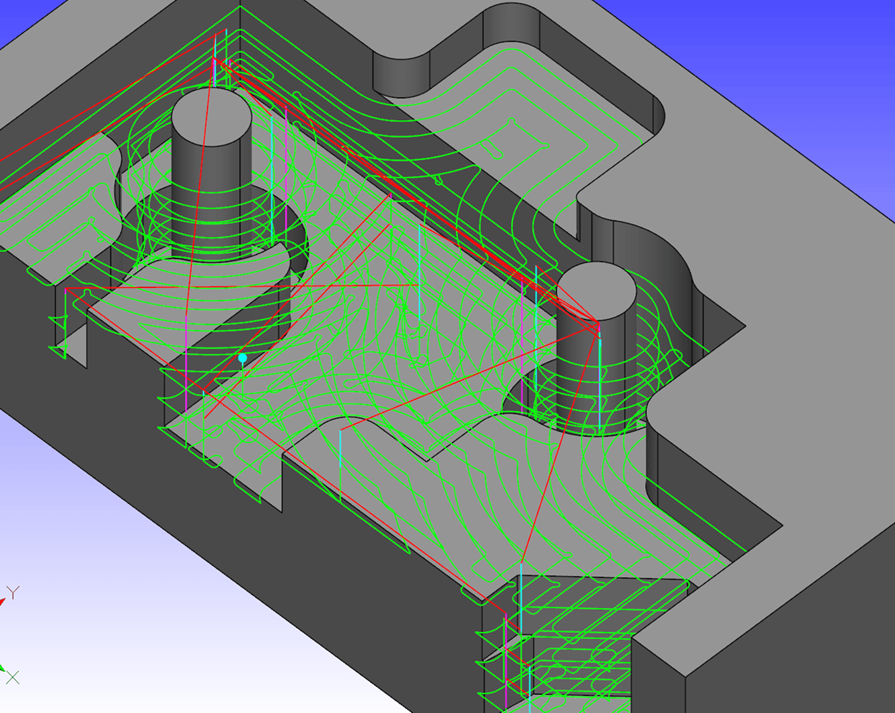

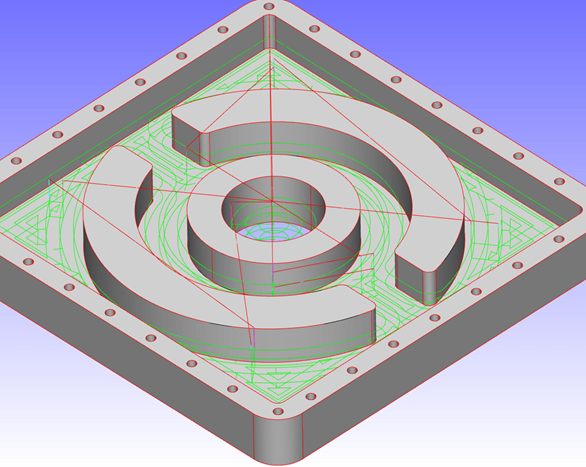

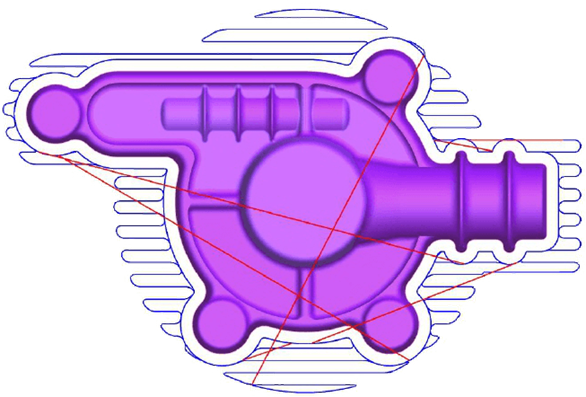

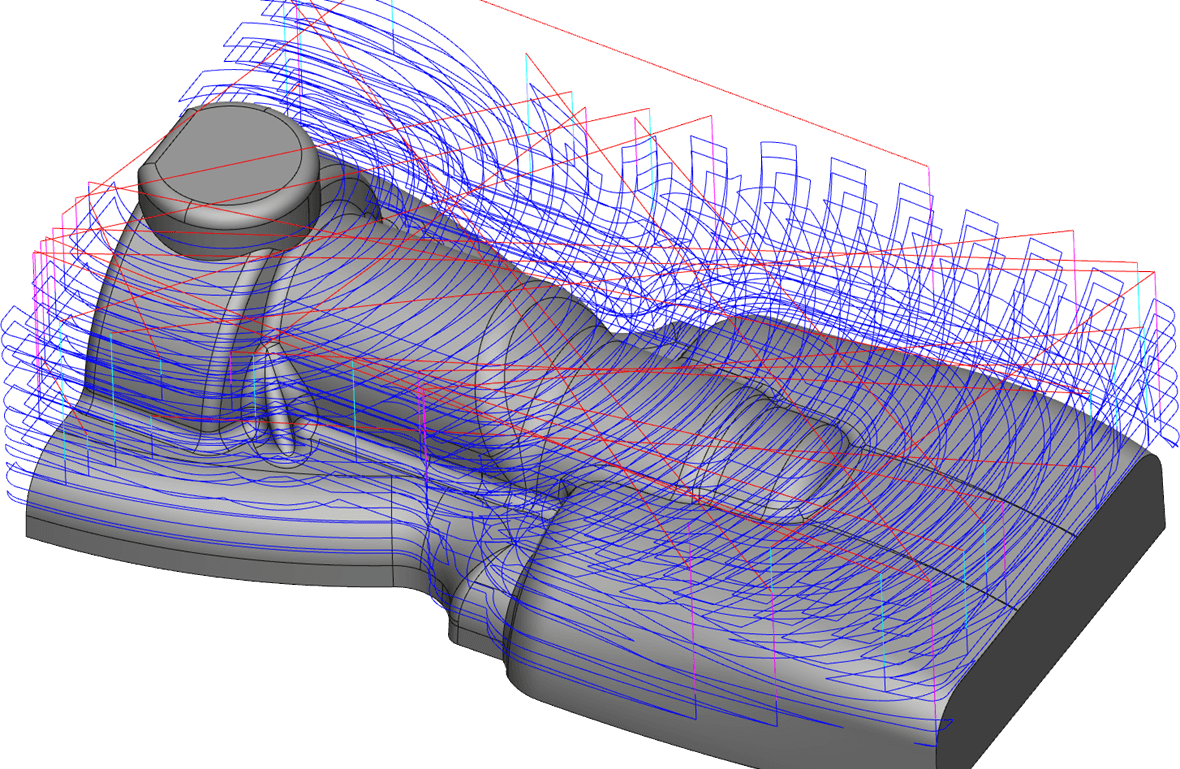

Horizontal Roughing - Offset/Modell Horizontal Roughing - ZigZag

Horizontal Roughing - ZigZagAll roughing strategies work according to the Z-level principle. All roughing strategies split the machining area into individual levels. In this way a tool-friendly milling operation takes place over the entire process on a Z-constant level. In order to minimize the remaining rest material on flat areas can roughing planes automatically be positioned for an optimization of the distribution of planes.

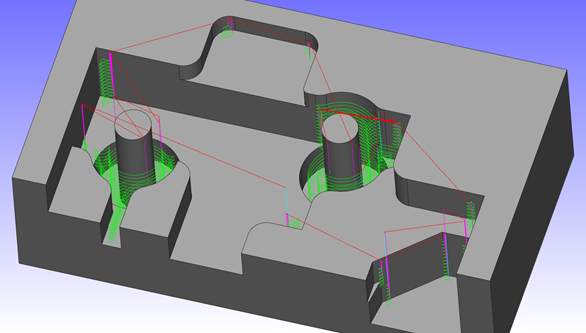

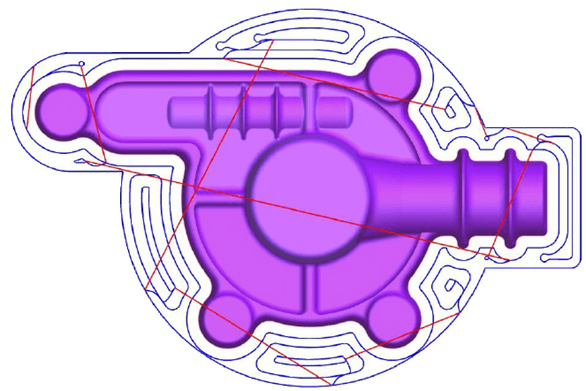

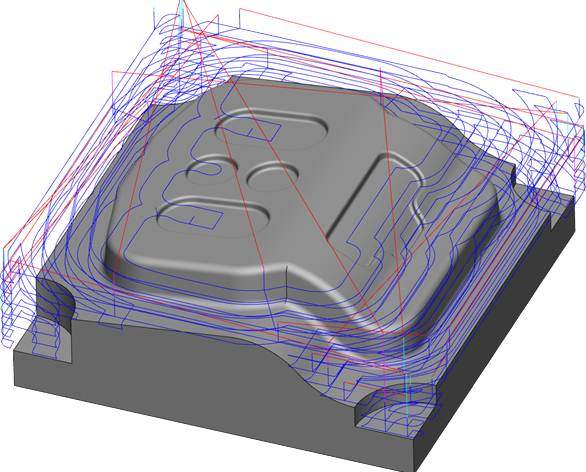

Every roughing strategy has special properties applied to different machining situations. For example the roughing strategy “offset” is particularly well-suited for the use with thin-walled parts or pocket-shaped forming areas or concave forms (hollow forms). Even if a directed cutting direction such as up-cut/ climb milling is required over the entire roughing process, the offset roughing should be the first choice.

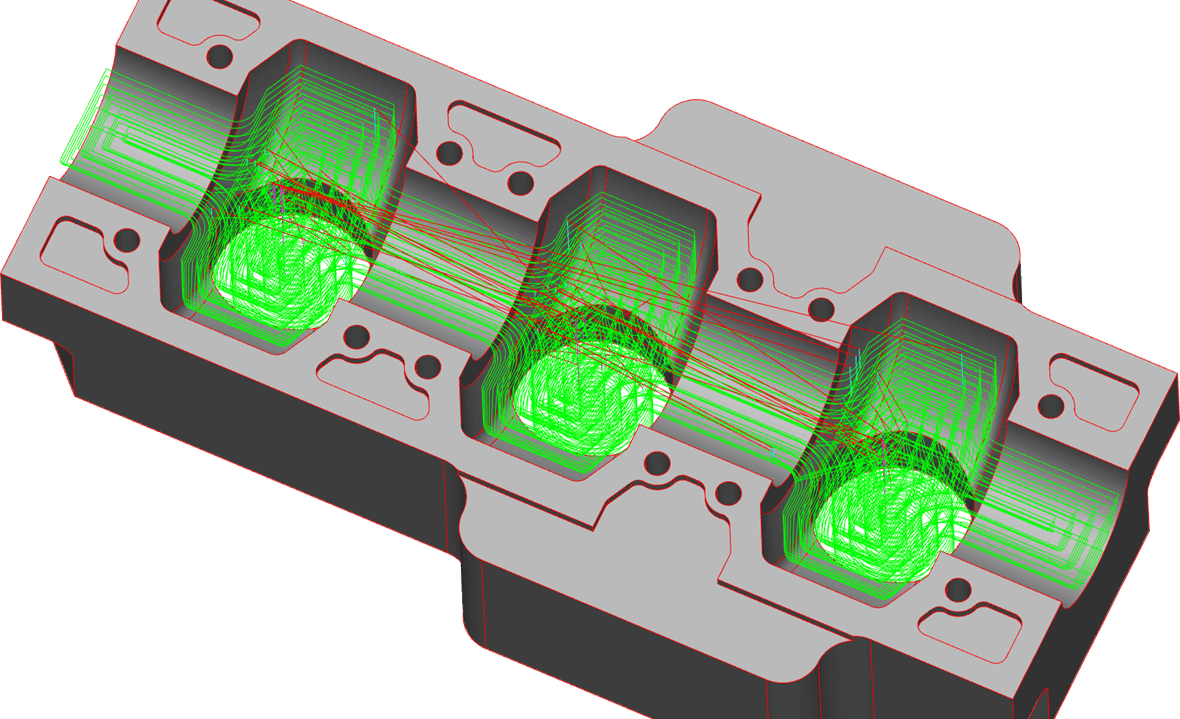

Roughing of concave forms with the strategy “offset-roughing”.

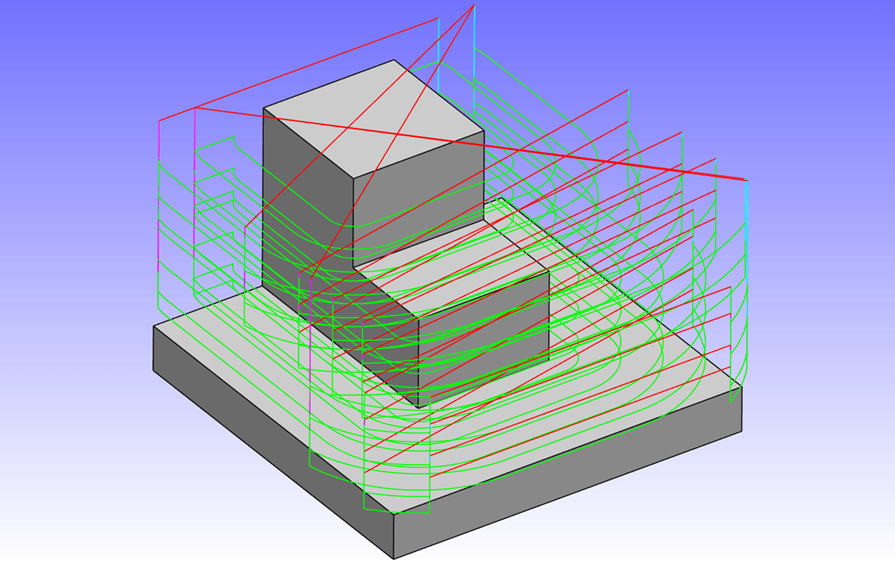

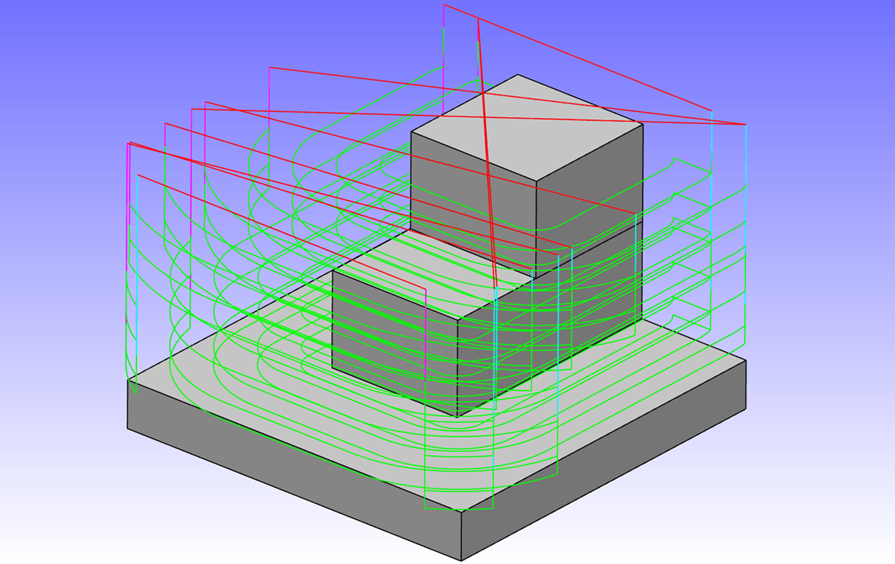

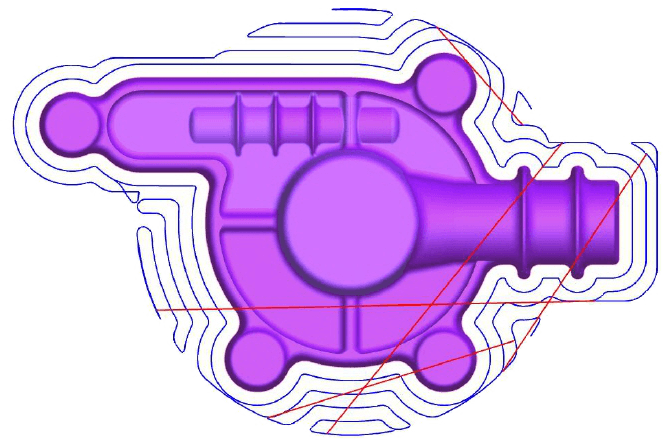

Roughing of convex forms with the strategy “offset/model” and “pendulum roughing”. The advantages of these strategies will be seen for example in less empty runs, in external entry points and a better chip removal.

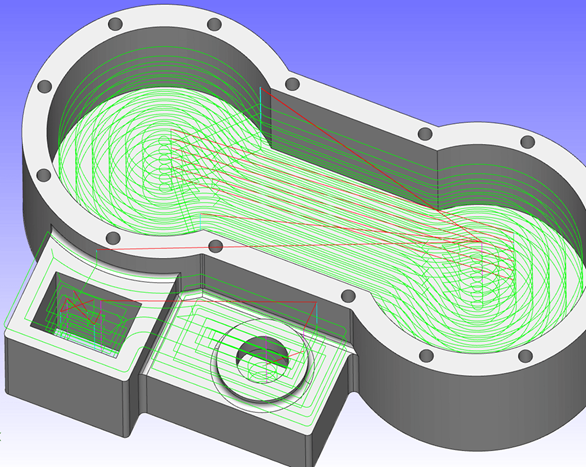

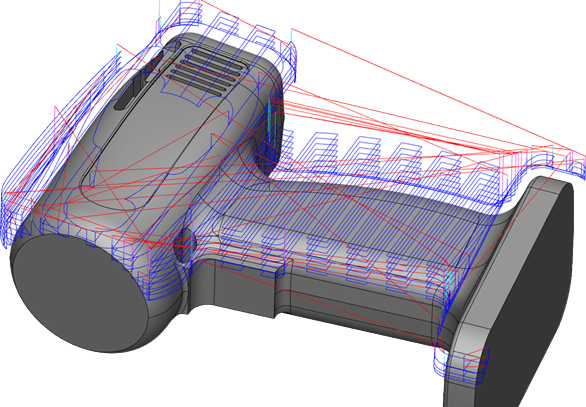

All machinings from roughing over finishing can be limited by boundary contours or machining ranges. The boundary contours can be added per DXF-drawing or be extracted from flat edges or be created using the functions for drawing “polyline”, “line”, “circle” or “rectangle”. The first example shows the limitation of a roughing operation. The boundary contours can automatically be created with the function “extract edges” among other things.

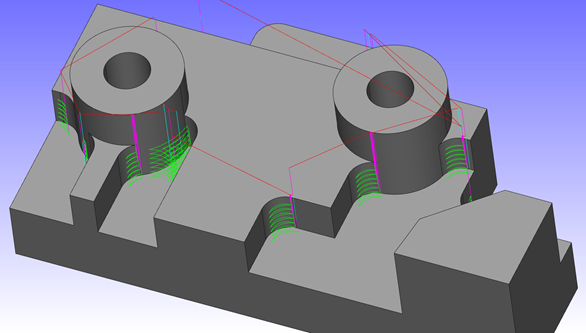

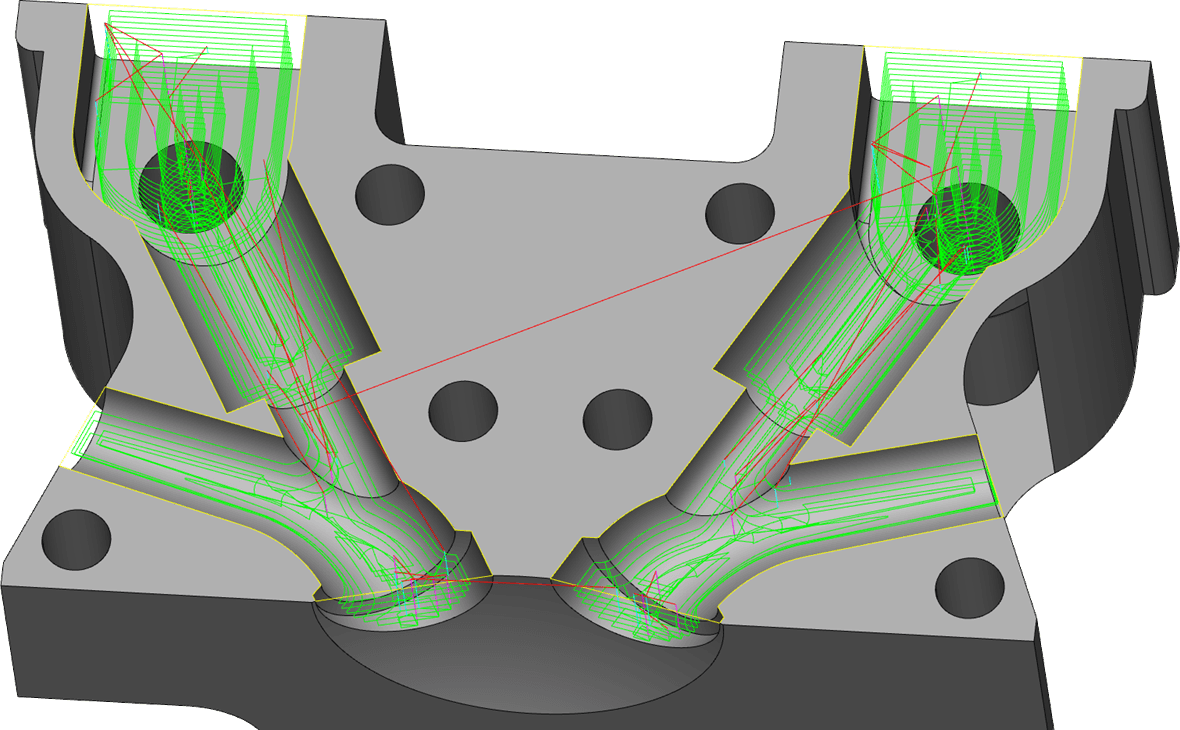

Restmaterial Roughing

Using the strategy “Z-level restmaterial roughing” it is possible to remove with a smaller tool areas of residual material that were not detected due to a too large tool. Condacam automatically determines all areas of residual material before these have been removed with a roughing operation. For instant it can be pre-roughed with a larger tool. Whereby better rates of material removal can be obtained with larger tools. Following all restmaterial areas can be reworked with the strategy “Z-level restmaterial roughing” and with a smaller tool.

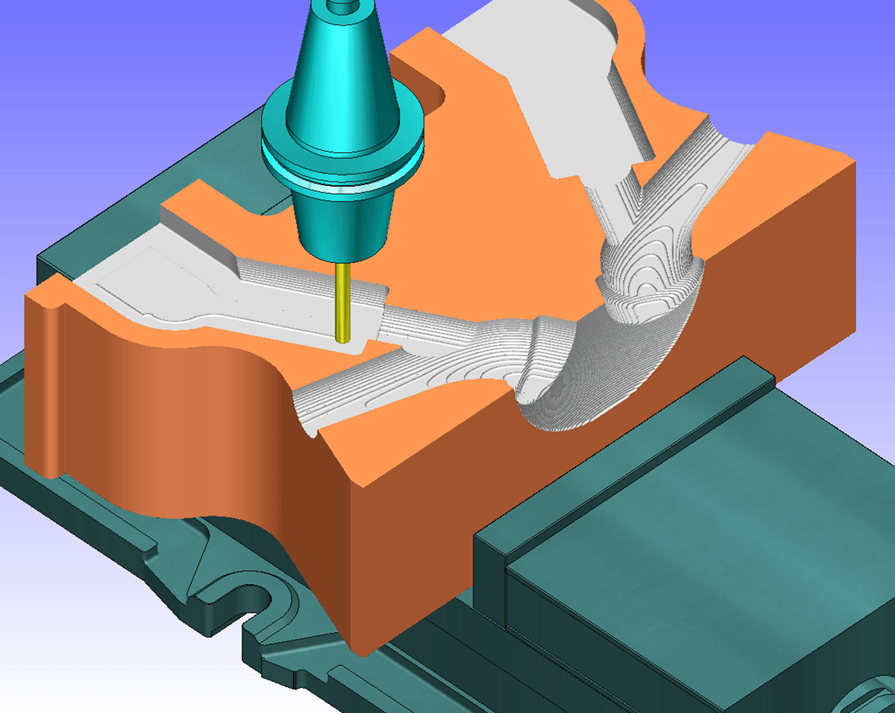

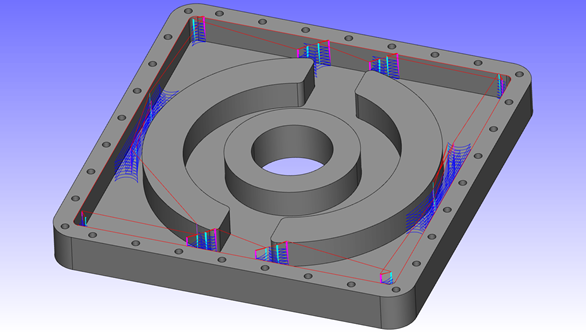

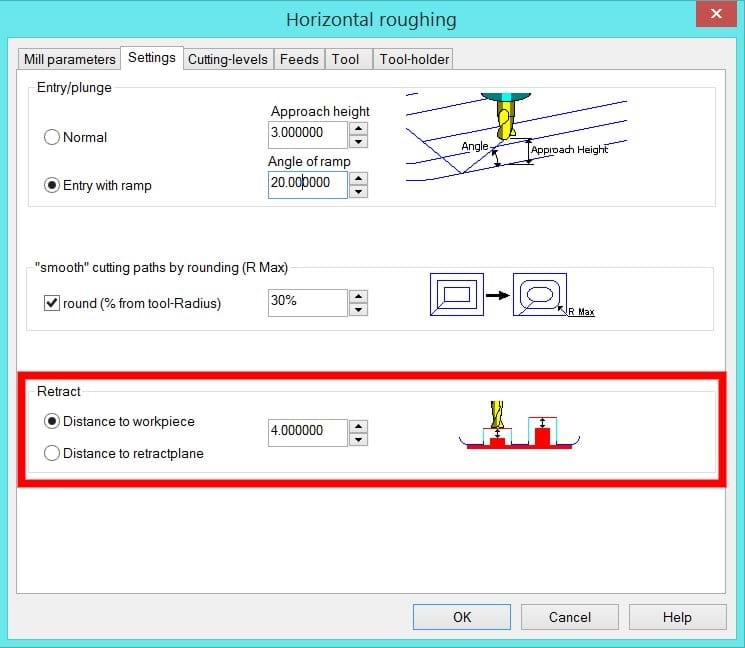

"Virtual Stock-Tracking"

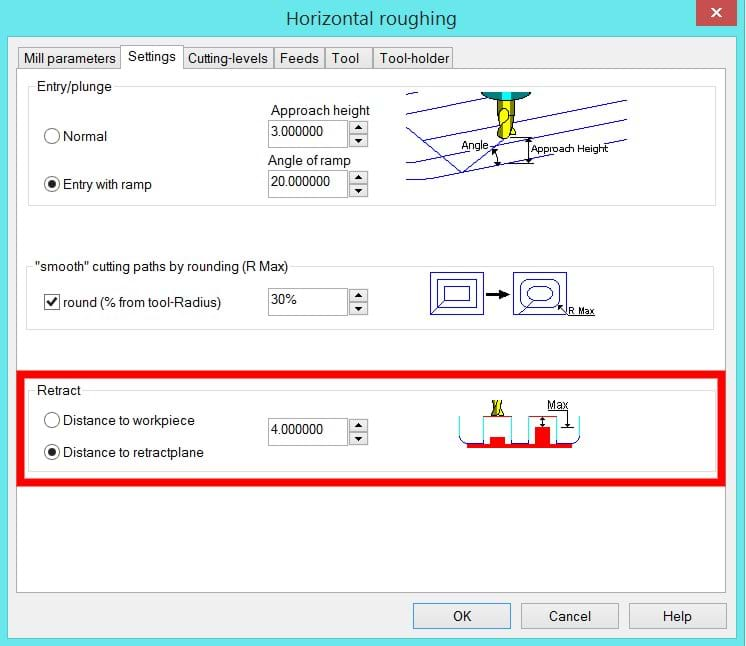

Additionally all roughing strategies possess a virtual stock-tracking. Condacam internally calculates for every cut a virtual stock. It is hence possible to reduce the drive-over height to a minimum during the roughing. This will lead to effective tool paths and reduces the machining times.